Fiber laser machines tailored for high performance cuts

Performance, compact size, affordable cost

The competitive advantage of laser cutting at the Industry time of 4.0 passes through machines that

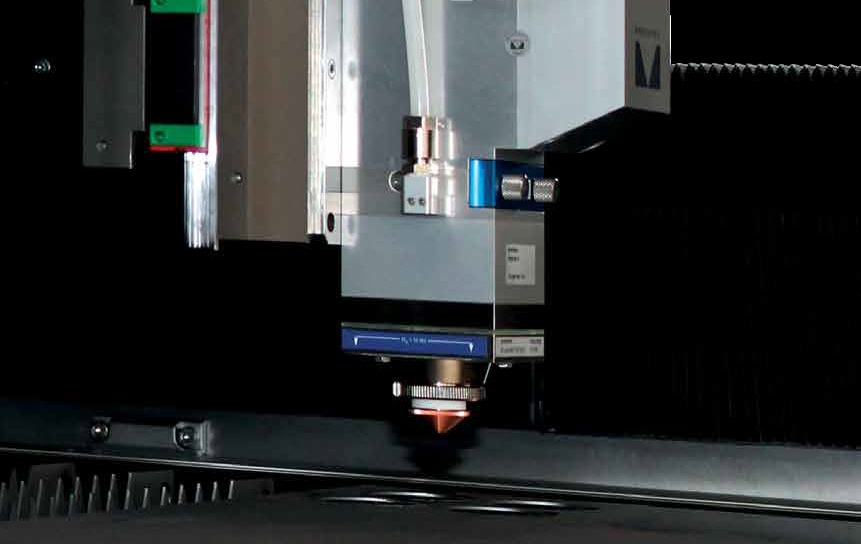

- Perform a highly efficient, fast and precise cut to obtain a finished product or ready for subsequent processing (welding, bending …)

- Are interfaced with the design and the rest of the production

- Can send information to auto-correct their programs

- Are reliable thanks to high quality components

- Have compact dimensions to fit into confined spaces

- Are ready for use, once delivered

This is how Applyca builds its own tailor-made fiber optic laser machines, especially designed for processes that require continuous position inversions, for example, in the construction of the teeth for circular saw blades.

However, thanks to our transversal expertise in the field of industrial automation, we also use lasers for functions that go beyond cutting, welding, marking. For example, we used it to clean rust or paint large surfaces.

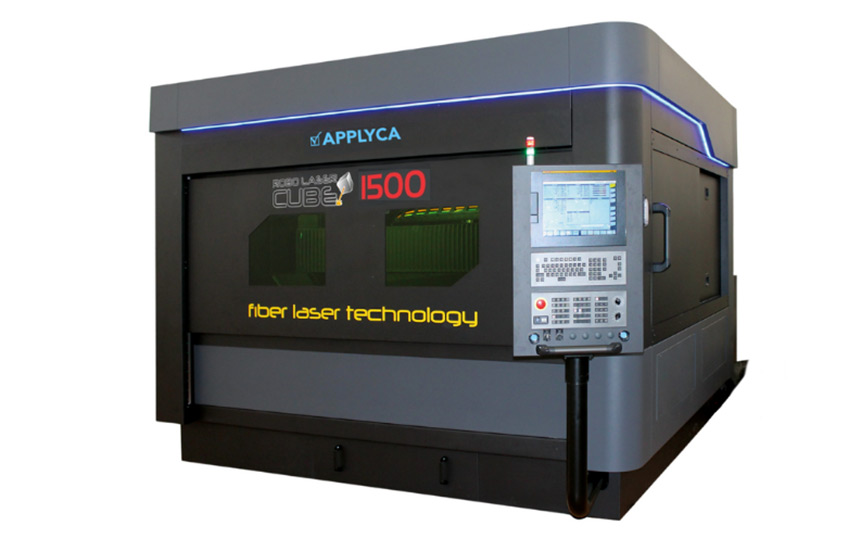

Robo Laser Cube: a model to be customized as desired

At Applyca we build to measure and, at the same time, we have created Robo Laser Cube as a privileged starting point for many of the requests we receive. It is a small and compact fiber laser cutting machine for high quality processing, equipped with a Fanuc control and robot. Integrating the technological components of this well known Japanese company is, for us, the certainty of quality and assistance. Fanuc has worldwide connections equipped with specialized support and service networks, of which, we are proudly part of.

Robo Laser Cube is equipped with a working area of 1500 × 1500 mm, therefore easy to integrate in small spaces, with an automated loading and unloading table that can start a new cutting phase in less than 5 seconds, while managing multiple orders on the same sheet metal. The installed CAD CAM then discriminates the individual pieces, picks them up using a robot with a versatile gripper and arranges them in the job area. The linear magnetic motors used, guarantee remarkable speed, high precision up to H7 tolerance and minimal mechanical wear, reducing the need for maintenance.